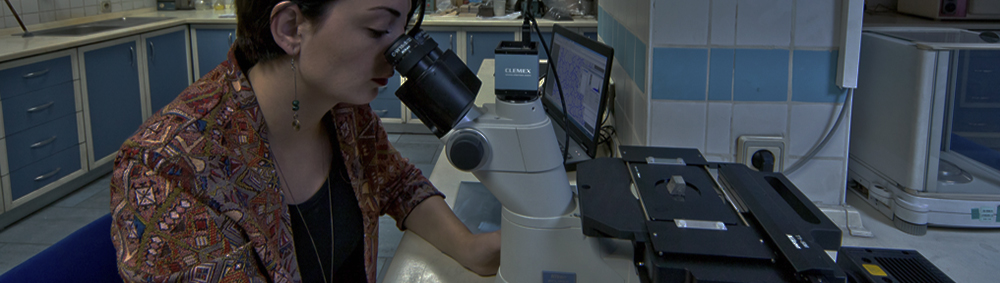

The measurement of the raw or machined castings by using various callipers, micrometers and gonimeters.

Surface roughness values are tested by special surface roughness measurment equipment. This type of test is mostly required for machined castings.

The thickness of the coating applications like oil or painting can be measured.

The thickness of the wall of the castings are examined with ultrasonic test equipment.

The dimensions of the parts can be examined with 3D coordinate mobile measuring device (Mobile CMM).

The installation suitability of the castings are tested with help of various apparatus, stencils and gauges.